| Monthly Tech-Tip | No tracking! No ads! |

Heres evidence that using a black stain is safer than manganese dioxide

A search for "ceramic stain toxicity" shows 19 digitalfire hits out of 32. Pretty well all of these pages refer to the increased toxicity of metal oxides over stains. No alarm. However, a search for "manganese dioxide toxicity" (lower right) is alarming (with disturbing words like neurotoxicity, movement disorders, Parkinson’s, distonia, liver disease, iron depletion, etc.). So then, why are so many potters still using recipes for black that contain high percentages of manganese dioxide? Although many black glazes use a combination or iron oxide and cobalt (e.g. 10%/2%), that does not work as well so manganese is still commonly employed (along with other metal oxides). There is a better way: Black stain in a proven base recipe (like GA6-B, G2934, G2926B), as little as 4% is possible. The decreased bioavailability of stains and and the much lower percentage needed make them a no-brainer for coloring glazes more safely.

Related Pictures

Stains are better in black glazes

5% stain vs 15% metal oxides

This picture has its own page with more detail, click here to see it.

Consider the hazards and hassles before choosing a black matte or gloss recipe that has high individual or combined percentages of manganese dioxide, cobalt or nickel.

Gloss blacks: These are super popular right now as the base for layering of reactive glazes. DIY dipping versions thus make a lot of sense. They make even more sense when they don’t turn to jelly in the bucket because of the high percentage of red iron oxide in all blacks made using metal oxide colorants. And when the total percentage of pigment is as high, or higher than 15%. And when the pigments cause crystallization (especially when overloaded).

Matte blacks: The human eye can detect even slight differences in the degree of matteness (which is very difficult to keep consistent). Raw metal oxides affect the matteness, especially when overloaded with pigment. They are prone to cutlery marking if too matte. By using stains manufacturers, and even potters, have learned to tune recipes (lower left) and firing schedules to achieve consistency and functionality (even tourist souvenirs (lower right) feature them now). With stains, only one material is producing the color, its percentage (which can be as low as 4%) can be tuned.

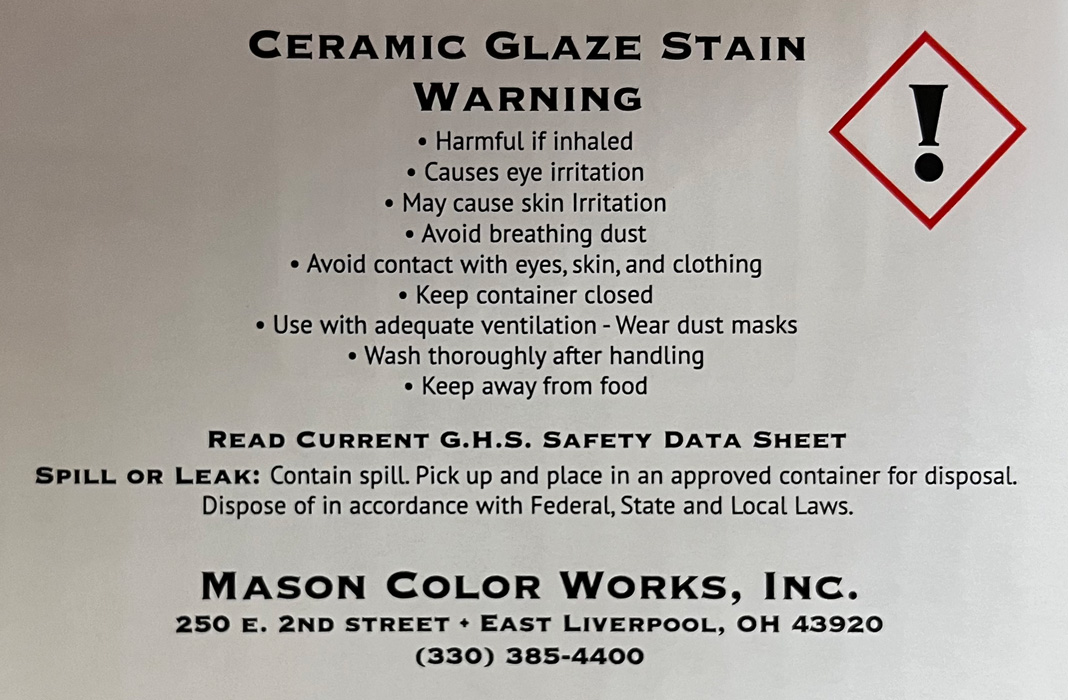

Ceramic Stain Toxicity Label

This picture has its own page with more detail, click here to see it.

Google searches on ceramic stain toxicity generally confirm the relative safety of these products, compared to raw metal oxides, as powders in use in production. Of course, saturating glazes with stains, especially reactive fluid melt glazes, can invite leaching issues the same as with oxide colors.

Why would I use a heavily pigmented black glaze on a food surface?

This picture has its own page with more detail, click here to see it.

These are actually two different cone 6 base glazes to which I add a black stain. I trust them because I know what is in them, I formulated and perfected them myself: G2926B clear and GA6-B Alberta Slip base. They are durable, fit my clay bodies, melt well yet can host a stain without loss of gloss. I even know the chemistry, both have plenty of SiO2 and Al2O3, that is a hallmark of durability. I fired these using the PLC6DS schedule. I add 5% black stain to the former and 4% to the latter, both yield a jet-black. The GA6-B requires ball milling. Stains are inherently much safer to use than raw metal oxide colorants because they are sintered as colorant/stabilizer blends. And much less is needed. Contrast that with raw metal oxides, it is common to find black recipes containing up to 15% of blends of nickel, cobalt, iron and manganese! At times the manganese alone can be 8% or more! So, I feel relatively safe using these coloured glazes on a surface that will be exposed to hot and acidic liquids.

Control matteness by glaze recipe or firing schedule

This picture has its own page with more detail, click here to see it.

The clay is Plainsman M370. Fired at cone 6 using the PLC6DS drop-and-hold firing schedule. The inside glossy glaze is G2926BL. The outside glaze base is G2934BL matte. Both recipes contain 6% Mason 6600 black stain. G2934 is tricky to keep consistent because the matte surface is a product of both the chemistry and the firing schedule. Thus, we faced lots of testing when it became necessary to substitute Ferro Frit 3124 for the supposed equivalent, Fusion Frit F-19. Early results showed a little better melting, so the 10-15% glossy we normally add to move the stony matte toward satin is not needed. However, we still made an 85:15 batch for our more frequent slow-cool C6DHSC firings (otherwise this G2934 mug would have fired too matte). So with the two recipes and two schedules, I can produce four surfaces, from gloss satin to stony matte. Digitalfire was the first online source of a matte black functional glaze with tunable matteness.

Got a Question?

Buy me a coffee and we can talk

https://backup.digitalfire.com, All Rights Reserved

Privacy Policy