| Monthly Tech-Tip | No tracking! No ads! |

Glazing large bowls inside-and-out using brushing glaze

This wheel-thrown bowl is large, heavy and thick walled. There are pouring techniques to apply different colored dipping glazes to the inside and out but they are cumbersome and slow. It turns out that the hobbyist way of glazing is actually better - by brushing. I make these 500ml jars of brushing glaze and tune the percentage of gums to get the painting consistency and drying time best for me. Applying multiple coats by brush took only a few minutes and no wax resist or any other tools were needed. And it was easy to meet the two glazes in a straight line at the rim using the brush. The inside glaze is G2936B and outside is G2926B.

Related Pictures

Brushing glazes on large pottery items is surprisingly practical

This picture has its own page with more detail, click here to see it.

I applied this transparent inside and out on both bisque and bone-dry ware using only a small brush (of course a larger one or a fan brush would be better). I have done up to 35 lb bowls this way. This is not a commercial brushing glaze, it is a dipping glaze that we mix ourselves: G1947U. We add 10g CMC gum powder to one liter of a water-reduced version of the slurry. Blender mixing makes it possible to mix in the powdered gum and tune water content for the best brushing experience. The gum slows down the drying speed dramatically so there is plenty of time to brush it into place (while the wheel is turning). The gum also greatly increases the cohesion, enabling pouring it without drips, even in a long thin stream. Many pieces were done like this in recent kiln loads (including application onto a leather-hard 40-inch tall vase), the evenness of coverage was the best I have ever gotten (of any technique).

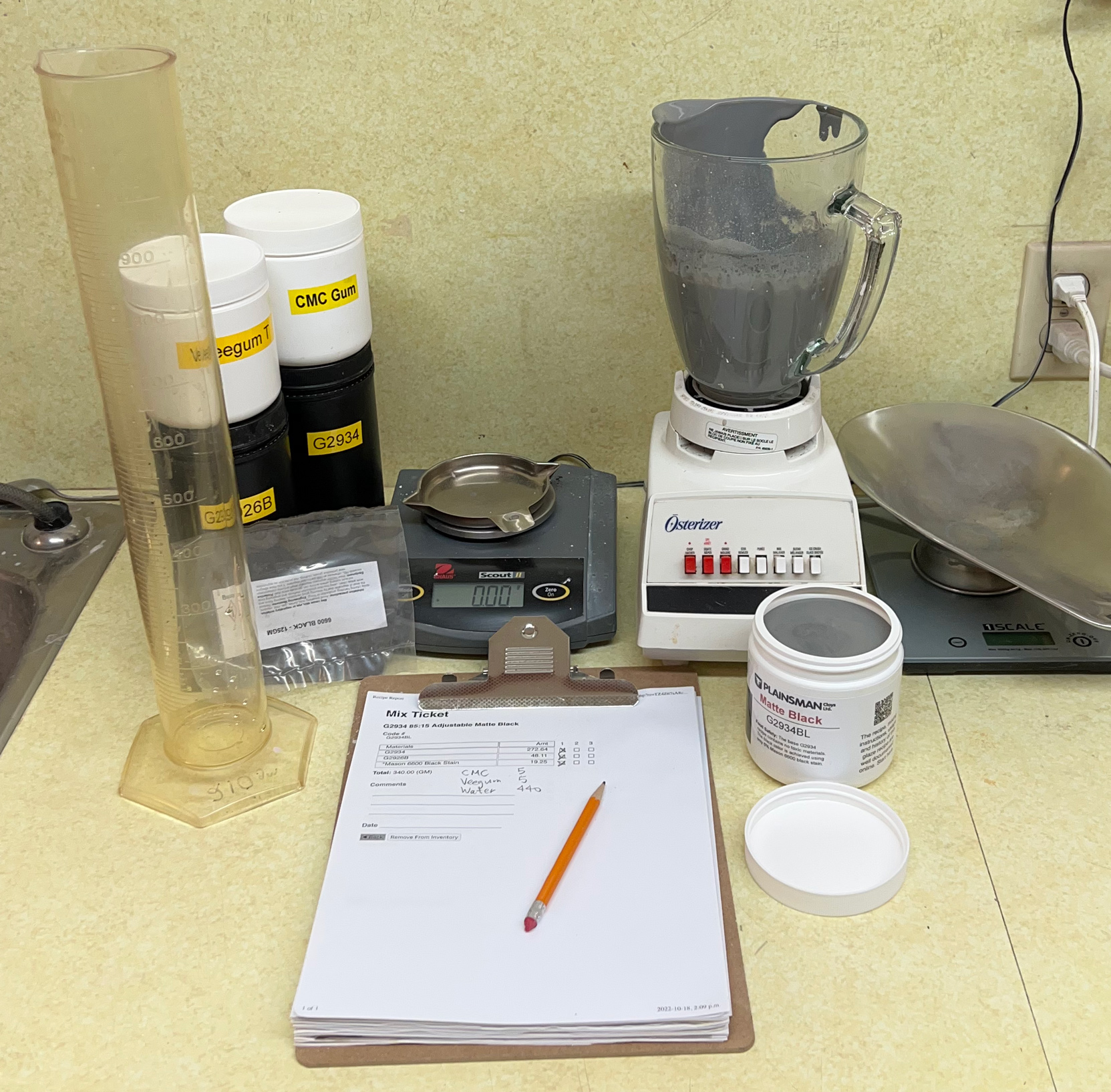

Here is my setup to make brushing glazes and underglazes by-the-jar

This picture has its own page with more detail, click here to see it.

Although I promote DIY dipping glazes, you can also make DIY brushing glazes. Let's make a low SG version of G2934BL. Weigh out a 340g batch of dipping glaze powder. Include 5g Veegum (to gel the slurry to enable more than normal water) and 5g CMC gum (to slow drying and impart brushing properties). Measure 440g of water initially (adjusting later if needed). Shake-mix all the powder in a plastic bag. Pour it into the water, which is blender mixing on low speed, and finish with 20 seconds on high speed. This just fills a 500ml jar. In subsequent batches, I adjust the Veegum for more or less gel, the CMC for slower or faster drying and the water amount for thicker or thinner painted layers. Later I also assess whether the CMC gum is being degraded by microbial attack - often evident if the slurry thins and loses its gel. Dipping glaze recipes can and do respond differently to the gums. Those having little clay content work well (e.g. reactive and crystalline glazes). If bentonite is present it is often best to leave it out. Recipes having high percentages of ball clay or kaolin might work best with less Veegum. Keeping good notes (with pictures) is essential to reach the objective here: Good brushing properties. We always use code-numbering (in our group account at Insight-live.com) and write those on the jars and test pieces. This is so worthwhile doing that I make quality custom labels for each jar!

Videos

Links

| Glossary |

Brushing Glaze

Hobbyists and increasing numbers of potters use commercial paint-on glazes. It's convenient, there are lots of visual effects. There are also issues compared to dipping glazes. You can also make your own. |

Got a Question?

Buy me a coffee and we can talk

https://backup.digitalfire.com, All Rights Reserved

Privacy Policy