| Monthly Tech-Tip | No tracking! No ads! |

What makes EP Kaolin unique? Are others as good?

In ceramics, EPK, or EP Kaolin, is used in clay bodies and glazes. Top right: Pure EPK is fairly plastic on wedging. But during the throwing process, it splits at the rim like this. The forming properties that it does have thus seem to be as much related to its stickiness and cohesion as plasticity. Without the help of bentonite or ball clay this would not be able to host the addition of feldspar and silica to make a usable porcelain or stoneware. But EPK shines in what it does as a slurry. Left: This slurry has been mixed to only 1.15 specific gravity and forms a thixotropic gel that clings to the spatula in an even layer. Bottom: This low specific gravity gel is thick enough that it will hold this heavy spatula vertical! Considering that our typical glazes have a specific gravity of 1.45 yet are still quite fluid it is evident just how much EPK can gel (and suspend a suspension). It is thus no surprise that it is the kaolin of choice in ceramic glazes. Are there other sticky kaolins that gel like this? Yes. Grolleg and New Zealand kaolin.

Related Pictures

EPK fired test bars, data, certificate and our data

This picture has its own page with more detail, click here to see it.

All of the test bars have been fired in this project to characterize a shipment of EPK (from cone 7-10 and 10R bottom to top). The dry and fired lengths and the dry and fired weights testdata was measured and entered into our Insight-live account. The results are shown in the red-titled columns (the drying shrinkage, firing shrinkage, absorption). The weights from the sieve analysis are also shown. And the calculation of water content of the plastic material (a very high 33.4%) and LOI (14.5%). We also like to take and upload a photo of the oversize material from the sieve analyses (to compare with past shipments) and of their manufacturers certificate of analysis.

Notice the data that the manufacturer considers important to include on the certificate that they send with the shipment: Particle size, particle surface area and moisture content. Of course, they would not be able to do all the tests we do. But our product is affected by the properties of the material, so we have to test.

#6 Tile Kaolin 2021 vs EP Kaolin 2020: Fired properties tell an unexpected story

This picture has its own page with more detail, click here to see it.

These test bars are fired at cone 10 reduction (top) and 10, 9 and 8 oxidation (downward) - they demonstrate the importance of measuring physical properties. The charts for each show data for drying shrinkage, firing shrinkage and porosity (water absorption). The left bars are #6 Tile kaolin and the right are EPK. These two kaolins had almost the same drying shrinkages in this SHAB test, that suggests the same plasticity. And the EPK fires whiter. So it should make a better plastic porcelain, right? Not so. In reality, #6 Tile kaolin is far more plastic - EPK requires the addition of significant bentonite to equal it (bentonite is dirty and that compromises whiteness). And EPK fires less vitreous - when feldspar is added color darkens. And, although both have extremely high firing shrinkages, the EPK is much higher than the #6 Tile (even though it is not as vitreous). Bottom line: #6 Tile is a better kaolin for clay bodies.

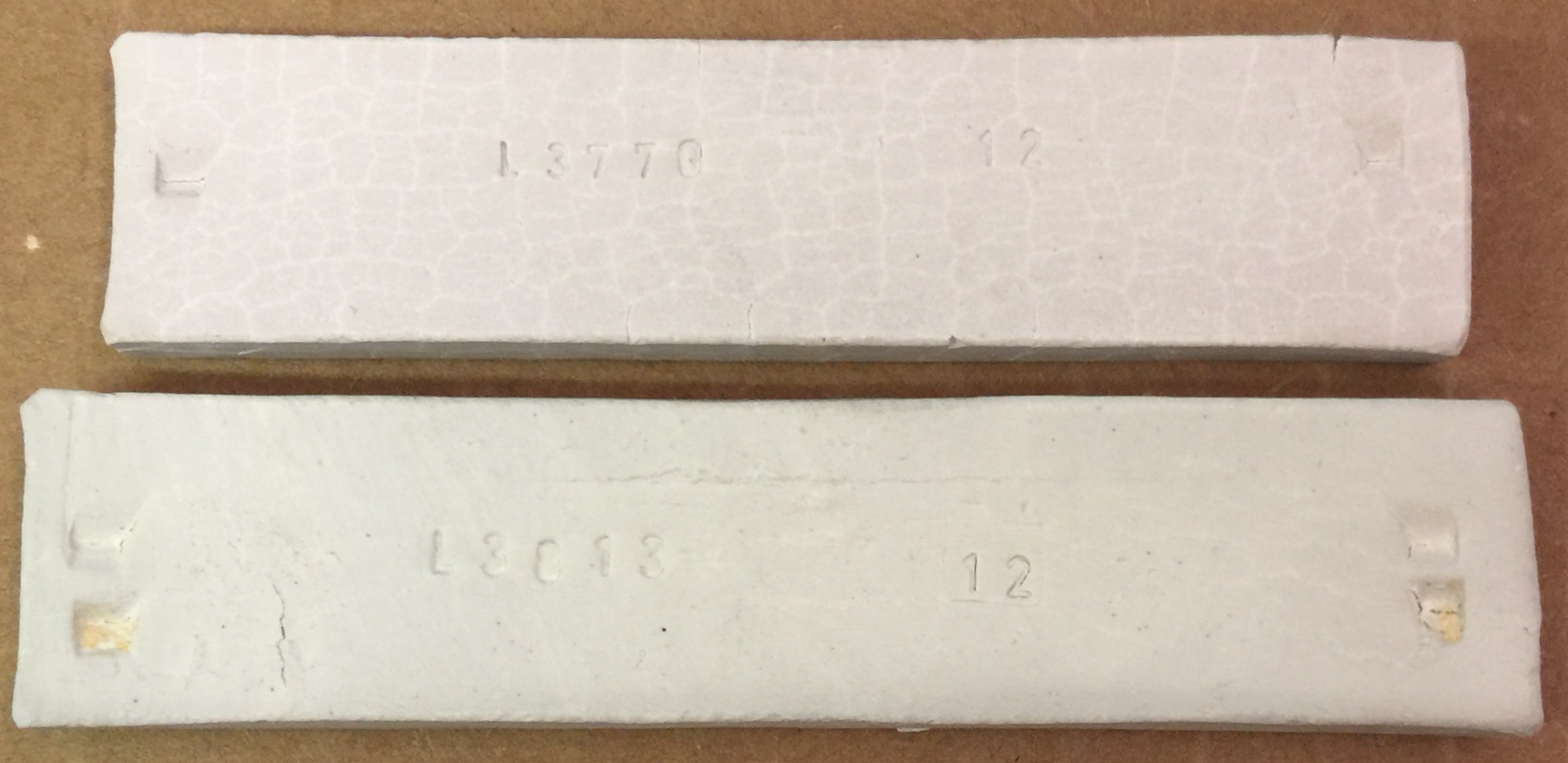

Two batches of EP Kaolin tested quite differently in 2018

This picture has its own page with more detail, click here to see it.

The EP kaolin has been mixed 70:30 with nepheline syenite. This creates a body that matures below cone 6. And it enables comparing the degree to which the two kaolins influence vitrification (and their contribution to fired color in a vitreous body). The darker one is more plastic, has higher drying shrinkage more soluble salts. These dry test bars were fired at cone 4-8 and had similar fired shrinkages and porosities. However, the one on the right fired whiter at all temperatures. These differences would impact the plasticity and drying shrinkage of bodies containing a significant percentage of the material. They would also influence the ability of this kaolin to suspend slurries.

EPK fired bar (top) vs Grolleg kaolin at cone 10R. Why shrinking more?

This picture has its own page with more detail, click here to see it.

From these SHAB test bars EP kaolin appears to have a much higher fired shrinkage. But half of that happened during drying. Still, EPK shrinks 4% more during firing. Yet Grolleg produces more vitrified porcelains. The EPK bar also appears to be whiter. Yet in a porcelain body, Grolleg fires whiter. That higher drying shrinkage proves that EPK is much more plastic, right? Not really. Throwing porcelains containing either require plasticity augmentation using similar percentages of bentonite. What do we learn? To compare materials like this we need to see them "playing on the team", in a recipe working with other materials. Don't rely on material data sheets, do the testing in your recipes.

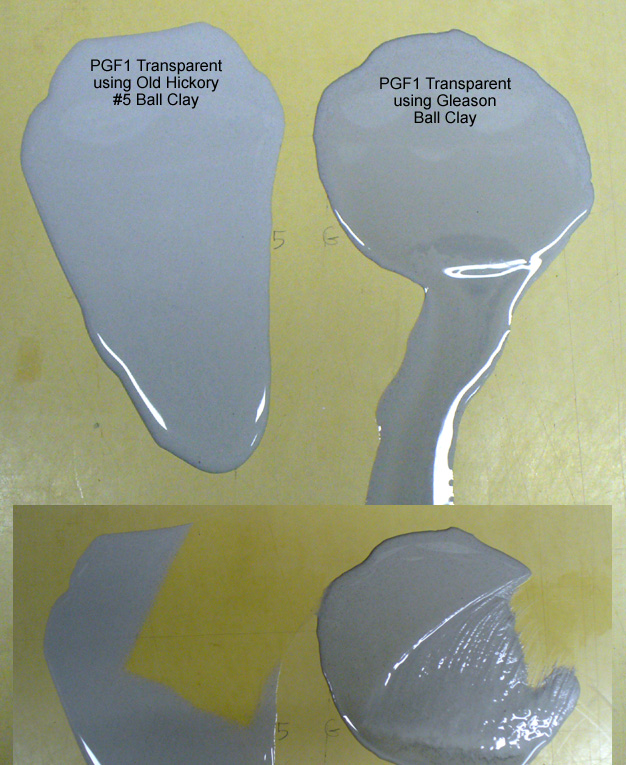

The ball clay you use to suspend your glaze is important!

This picture has its own page with more detail, click here to see it.

I poured 4 teaspoons of two glazes onto a non-absorbent butcher’s board and let them sit for a minute, then inclined the board. The one on the right employs Gleason Ball clay, the left one has Old Hickory #5 ball clay. Neither has any rheology modifier additions. The one on the right has settled and, on incline of the board, the watery upper is running off. The other has gelled and the whole thing is running downward slowly. Below that you can see where I have begun to sponge them off, the one on the right is sticky. The most amazing thing about this: This difference appears despite the fact that there is only 7% ball clay in this heavily fritted recipe.

Clay in a glaze recipes. Why is it there?

What happens when there is too much?

This picture has its own page with more detail, click here to see it.

If I put this on social, I might get 100 comments on the cause. Most would say it's applied too thick. That is not correct. At the top, it is too thick, but not at the bottom (where it is still cracking). Crawling during firing is almost certain.

Before offering any opinion, one needs to sanity check the recipe. This one, GA6-B, contains a lot of clay. Why do dipping glazes contain clay, usually kaolin, ball clay? To suspend the slurry, slow down drying, gel the slurry to make it thixotropic and harden the layer on drying. But their chemistry is also important, clays supply the all-important Al2O3 and SiO2 to the melt (which would otherwise have to come from feldspar). Certain clays excel at suspending. 15-20% EP kaolin, for example, is all that is needed. It’s not that plastic, but sticky and thixotropic (Grolleg and New Zealand kaolins are similar or even better). 10% of a gelling ball clay might be enough. However, 50% of a silty non-plastic clay might be needed. When the clay has too much influence, glazes shrink too much as they dry and then crack like this. Ones lacking clay (or employing one that is not suitable) have poor application properties (for dipping) and are powdery. This glaze has 80% pure raw Alberta Slip. That is a plastic clay, no wonder this is happening! 50% of it needs to be roasted.

Videos

Links

| Materials |

EP Kaolin

A kaolin that gels slurries (thus handy to suspend ceramic glazes). It is plastic and fires white enough that it is also valuable in porcelain bodies. |

Got a Question?

Buy me a coffee and we can talk

https://backup.digitalfire.com, All Rights Reserved

Privacy Policy