| Monthly Tech-Tip | No tracking! No ads! |

Testing the water content of a ceramic glaze

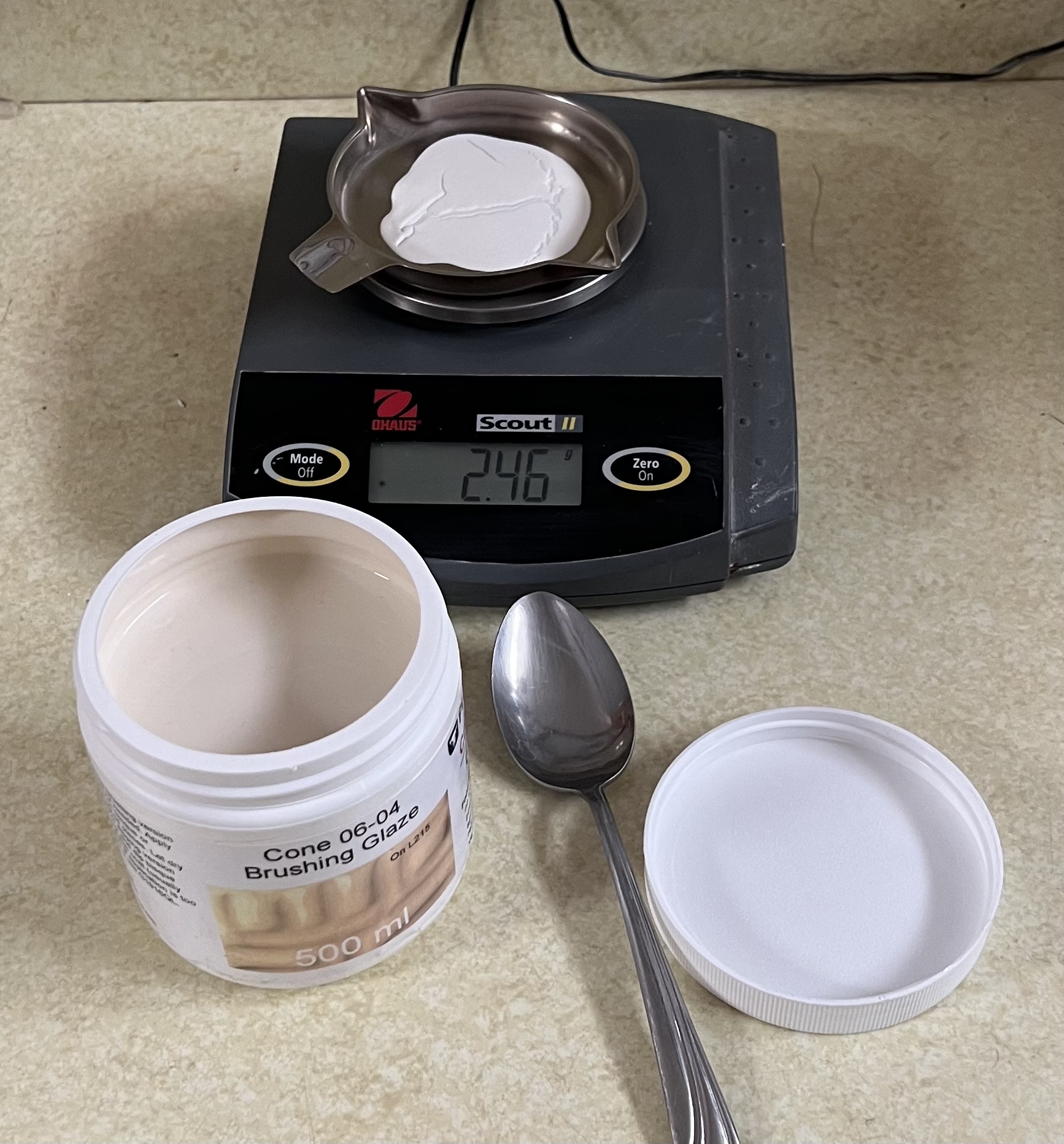

In this case I need to know the water content of a glaze to know how many grams of CMC gum to add to achieve a 0.5% addition (to improve brushing properties). I put a teaspoon of the glaze (well stirred) on the tray. It weighed 5.04g (this 0.01g scale is accurate to 1/100th of a gram). Then I dried it under a heat lamp and now it weighs 2.46g. The water content of the slurry is thus (5.04 - 2.46) / 5.04 * 100 = 51.2%. That means the solids content is 100 - 51.2 = 48.8%. I want to blender mix 0.5% CMC into this brushing glaze (because it is drying too fast). The jar with glaze weighs 680g and the jar itself weighs 35g. Thus 680-35=645. 48.8% of 645 is 315g of powder. 0.5% of 315 is 315 * .005 = 1.6g of CMC gum.

Related Pictures

Control gel using Veegum, brushing properties with CMC gum

This picture has its own page with more detail, click here to see it.

This is G1214Z1 brushing glaze (with 5% titanium added). For a 340g powder batch (to get a pint) my initial target is 5g CMC gum and 5g Veegum. CMC controls drying speed and Veegum the amount of gelling. I first mix the CMC with the powder and shake the whole batch in a plastic bag. Then I add it all to 440g of water in the blender jar and mix it well (making sure no agglomerates remain (stage 1). Stage 2 is adding the VeeGum slowly, while high-speed blender-mixing, this is important because it enables tuning the degree of gel (which cannot be predicted). Because this recipe has little clay, it took all 5g of Veegum without overgelling (the entire mass moved freely in the mixer jar). But it did gel overnight (so 4g would be better next time). By contrast, it is the brushing behavior that demonstrates whether the amount of CMC is right. Not enough and coats dry too fast and go on too thick. Too much and it dries too slowly and too many coats are needed.

Videos

Links

| Glossary |

Water Content

|

| Tests |

LOI/Density/Water Content

LDW LOI, density and water content test procedure for plastic clay bodies and porcelains |

Got a Question?

Buy me a coffee and we can talk

https://backup.digitalfire.com, All Rights Reserved

Privacy Policy