| Monthly Tech-Tip | No tracking! No ads! | |

Kingman Feldspar

Description: Potash Feldspar

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.10% | 0.01 | |

| K2O | 12.01% | 0.73 | |

| Na2O | 2.80% | 0.26 | |

| Al2O3 | 18.72% | 1.05 | |

| SiO2 | 66.17% | 6.31 | |

| Fe2O3 | 0.11% | - | |

| LOI | 0.08% | n/a | |

| Oxide Weight | 572.75 | ||

| Formula Weight | 573.21 | ||

Notes

No longer available. When looking for a substitute, note how high KNaO content in this. It is much higher than Minspar or Custer. G200 HP, although having a different ratio of K2O/Na2O shares the high KNaO content (and other oxides levels are very similar).

Related Information

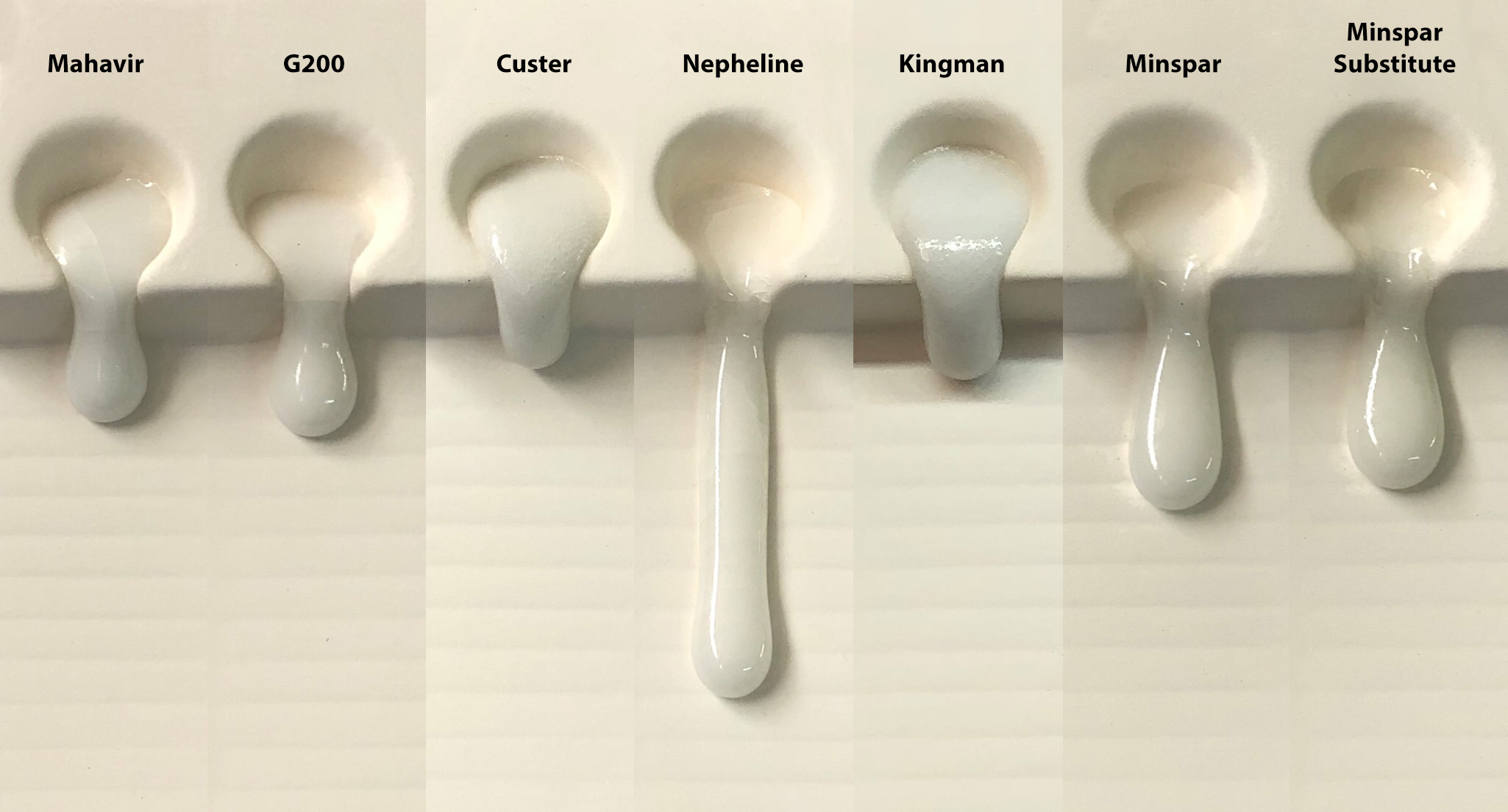

Which is the champion melter of American/Canadian feldspars?

This picture has its own page with more detail, click here to see it.

Feldspars are employed in glaze recipes as melters. So comparing their melt fluidities should be helpful in deciding if one can substitute for another (of course, if possible, a soda-predominant feldspar should be substituted for another soda spar). Feldspars don't melt alone at cone 6 (2200F) so we mixed each with 15% Ferro Frit 3195 (we consider a feldspar a material that sources KNaO). Nepheline Syenite, this is A270, is the champion melter here. Other similar ones can be spotted easily. In the end, degree of melt is a valid consideration in determining if one feldspar is a viable substitute for another in a recipe. Even if the feldspar you want to substitute does not melt as much a little frit can be added to the recipe to make up for the difference (e.g. 3-5%).

Links

| Materials |

Custer Feldspar

The most common potash feldspar used in ceramics in North America. While having been a standard for many decades its supply appears in doubt in 2024. |

| Materials |

G-200 Feldspar

|

| Typecodes |

Feldspar

The most common source of fluxes for high and medium temperature glazes and bodies. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://backup.digitalfire.com, All Rights Reserved

Privacy Policy